- Product description

- Media & Downloads

- Accessories

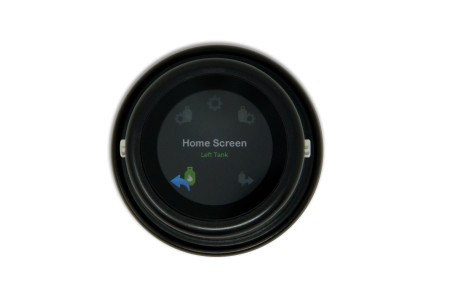

Mopeka Pro Check Universal - Steel tanks

The Mopeka Pro Check Universal sensor is the next generation of the powerful Pro Check technology, offering the user the same great ease of use and connectivity, but with the addition of new and useful features:

- Improved accuracy - the Pro Check already has an accuracy level of 99%... the Pro Check Universal will increase this accuracy to 99.5%

- Additional liquids - the Tank Check app that accompanies the Pro Check Universal adds additional commodities to the drop-down list, including diesel, oil, water, propane, butane, water and other liquid commodities

- 63% longer battery life of the sensor compared to the original Pro Check

With strong magnets that attach to the bottom of the cylinder, spacers and dielectric grease

Improve your outdoor cooking experience and use of propane-fuelled patio heaters with our advanced digital propane tank gauge. The Pro Check Universal is an essential tool for any outdoor enthusiast, providing real-time updates on your propane level via a seamless mobile app connection. In addition, the sensor can also be used to measure other liquid commodities such as oil, diesel and water.

Effortless installation - Say goodbye to complicated installations. Our tank sensor simply attaches to the bottom of your tank with strong magnets or mounting collars and can be attached in seconds. Our robust magnets and mounting rings ensure that the sensor sits firmly on your motorhome's propane tanks in any terrain, so you don't have to worry when travelling. It is designed for tanks up to 946 litres/ 250 gallons in size.

Extended Battery Life - The Mopeka Tank Sensor is now equipped with a much longer lasting battery, ensuring that it will remain operational for extended periods of time without the need for replacement. The battery is replaceable if required.

State-of-the-art technology - The Mopeka Pro Check Universal features an integrated temperature sensor, tank level indicator, configurable sampling timing, firmware updates and customisable alarms/warnings, all designed to improve the quality and accuracy of measurements. The device can be used with both vertical and horizontal cylinders, making it a versatile and reliable option for tank monitoring.

Free mobile app - Download the user-friendly "Tank Check" app for free from the Apple and Google Play stores. The app supports an unlimited number of tanks and sensors and allows customisable alarms to suit your needs.

Upgrade to the Mopeka Pro Check UNIVERSAL sensor and enjoy a whole new level of convenience, accuracy and precision in monitoring all your tank levels.

Safety and warning notices

Safety and warning instructions for Mopeka ultrasonic sensors with CR2032 battery

Introduction: Please read these safety instructions and warnings carefully before installing or using the Mopeka ultrasonic sensor. Follow the instructions to ensure safe use and avoid potential hazards.

1. general safety instructions

- Read the instructions: Keep these instructions for future reference and read them completely before using the device.

- Children: Keep the device and the CR2032 battery out of the reach of children as the battery can be swallowed and could cause serious injury.

2. warnings about the battery

- Ingestion hazard: CR2032 batteries can cause serious internal injury if swallowed. Seek medical attention immediately if the battery is swallowed.

- Explosion and fire hazard: Do not charge, disassemble or dispose of the battery in a fire. There is a risk of explosion and fire.

- Avoid short circuits: Ensure that the battery does not come into contact with metallic objects to avoid short circuits and overheating.

3. environmental and operating conditions

- Recommended environment: Only operate the sensor within the specified operating conditions (temperature range and humidity limit). Extreme environmental conditions such as high humidity or temperatures can impair sensor performance.

- Protection against chemicals: Do not expose the sensor to aggressive chemicals or corrosive substances, as these can damage the electronics.

4 Mounting and mechanical stability

- Mounting instructions: Ensure that the sensor is stable and correctly mounted to avoid mechanical damage. Incorrect installation can lead to measurement errors or failure of the sensor.

- Stable mounting surface: The sensor should not be installed on unstable or highly vibrating surfaces to ensure measurement accuracy.

- Flow direction: Ensure that the flow direction of the sensor is installed correctly according to the instructions on the device.

5 Electrical safety during installation and maintenance

- Safety measures during installation: Only install the sensor with clean and dry contacts to prevent short circuits. Electrical safety precautions must be observed during all installation and maintenance work.

- Proper installation: Installation and maintenance of the sensor should only be carried out by qualified personnel to ensure safe operation of the sensor.

6 Battery safety and correct handling

- Correct polarity: Ensure the correct polarity (+/-) when inserting the battery to prevent damage to the device.

- Replacement by qualified personnel: If the battery needs to be replaced, it is recommended that the replacement is carried out by qualified personnel to avoid damage.

- Temperature and sunlight: Avoid exposing the sensor and battery to direct sunlight or high temperatures to reduce the risk of overheating.

7 Storage and disposal

- Safe storage: Keep the sensor and spare batteries out of the reach of children and in a dry, cool place to prevent corrosion or battery leakage.

- Disposal of batteries: Never dispose of empty or damaged batteries in household waste. Instead, take them to an authorised collection point for batteries or a collection point to avoid environmental and health risks.

- Environmentally friendly disposal of the sensor: Dispose of the device in accordance with the applicable guidelines for waste electrical and electronic equipment (WEEE). Remove the battery before disposal and dispose of it separately.

8. maintenance and inspection of the sensor

- Regular inspection: Check the sensor every six months

Manufacturer Contact information

Manufacturer Contact

Mopeka Products, LLC

1223 Industrial Drive, Suite A

New Braunfels, TX 78130

USA

EU Contact

HybridSupply GmbH

Roggenhorsterstr. 9b

23556 Lübeck

Germany