Additional valve protection is particularly important for gas-powered vehicles!

V-LUBE Valve Saver forms a protective film that minimises stress on the valves and valve seats. Active ingredient particles are released during combustion of the V-LUBE Valve Saver and transported to the valves and valve seats with the exhaust gas flow.

The surface of the valves and valve seats is coated by the V-LUBE active ingredient particles in the thermal environment of the exhaust gas flow (1400-2000 °C). The wear behaviour of the valves and valve seats is thus reduced to a minimum and is below the usual wear tolerances in petrol operation.

V-LUBE Valve Saver also has a cleaning and lubricating active ingredient component that allows V-LUBE Valve Saver to be added directly to the gas line via the V-LUBE Electronic Valve Saver Kit. This removes residues and contamination from injectors and gas lines (not to be used with „platelet injectors“).

Efficient valve protection with V-LUBE – All details at a glance

- Protects valves and valve seats from increased stress

- Cleans the nozzles and fuel lines

- Increases the economy and service life of the engine

- Provides optimum protection with the correct dosage

- Is compatible with the dosing systems available on the market

- Approved for injector additives (except „platelet injectors“) – the additive is dosed into the fuel line of the gas system and distributed via the injectors

- Long-life effect – lasting effect of the additive if dosing does not take place (up to 1,000 km)

- No negative effects on the catalytic converter

- Reduces maintenance intensity of petrol-powered engines (added to the tank)

V-LUBE quality promise – Because your engine deserves the best

Test procedure

Result: We have subjected the V-LUBE Valve Saver to rigorous testing and research to ensure the best possible valve protection for you.

TÜV inspects our product annually to ensure that the high quality remains unchanged.

Engine test rig test confirms valve protection in the high rpm load range without dosing system.

The practical driving test confirms the effectiveness of the additive in driving mode without a dosing system.

The 105,000 km long-term driving test under real-life conditions successfully confirms the effectiveness in the long-term test with dosing system.

126,000km long-term effect on the catalytic converter – long-term use of V-LUBE has no negative effects on the catalytic converter.

Summary of all tests

In the first studies (Studies 1 and 2), the focus was on testing the efficacy of the V-LUBE Valve Saver active ingredient without a dosing system. In the long-term practical trial (Study 3), the V-LUBE Valve Saver Kit was used to test the dosage under realistic conditions.

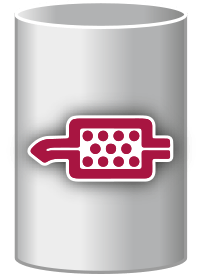

Efficacy study 1

Procedure: Various operating points were approached on the engine test bench and checked for wear rates in unadditivised operation. In order to test the effectiveness of the additive, the operating point with the highest wear was to be simulated using LPG with additives.

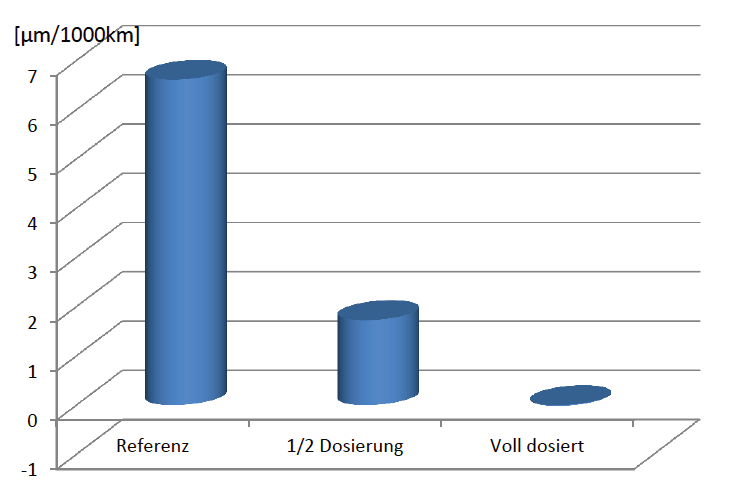

Figure 1: Measured valve clearance at 20h with additive compared to the previously determined wear rate.

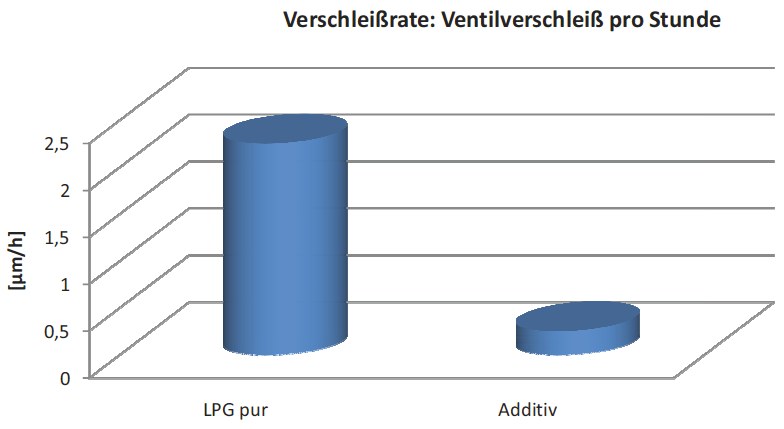

Effectiveness study 2

Extract from the driving test to analyse valve wear on a Peugeot 107 in LPG operation, additivated with the V-LUBE active ingredient. Carried out at the Saarland University of Applied Sciences.

Procedure: A Peugeot 107 with a liquid-phase autogas system was used for a 10,000 km practical test of the fuel additive. The vehicle has a 3-cylinder Toyota engine, which is not gas-proof. The vehicle was first driven without protective additives and the valve clearance was checked at a mileage of 12,500 km.

During the second, final check of the valve clearance at 10,347 km, an average valve deflection of 0.008 μm + 2 μm/1,000 km was measured over the entire test distance, which confirmed the effective valve protection of the fuel additive used as part of the practical testing carried out.

Figure 2: Averaged value (valve wear [μm/1000km])

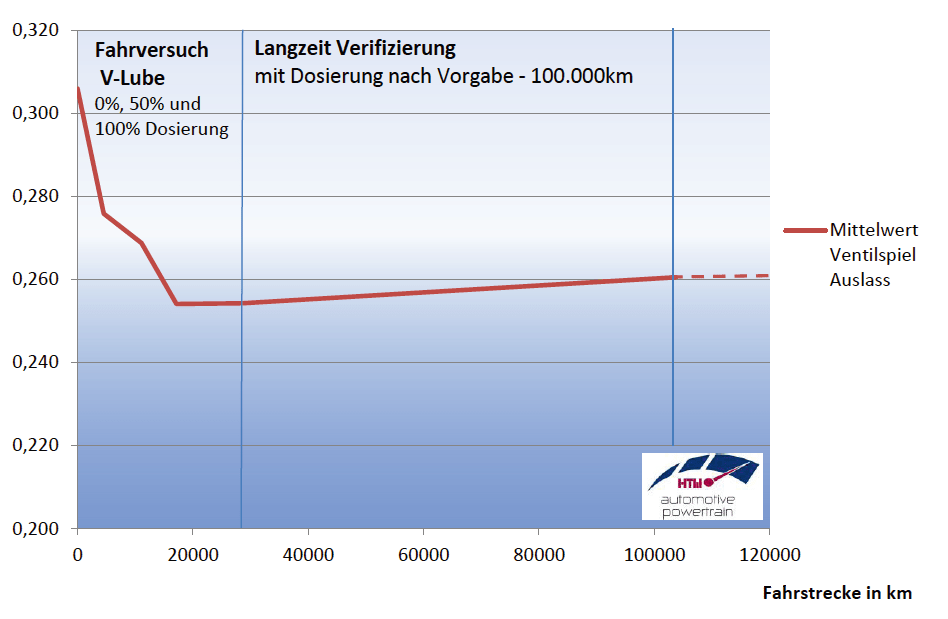

Effectiveness study 3

Extract from the long-term road test on valve wear in LPG operation, wear analysis on a Toyota Corolla Verso and testing of the V-LUBE Valve Saver Kit. Carried out at the Saarland University of Applied Sciences.

Procedure: In a Toyota Corolla Verso test vehicle, an alternative fuel system was retrofitted to enable operation with liquefied petroleum gas. A vaporiser system with an additive dosing system from the company V-LUBE was installed.

A 1.8 litre petrol engine from the VVT-i series is used in the vehicle. This engine is particularly suitable for this study, as no particular weaknesses in valve operation are known in petrol operation, but gas operation leads to valve impact.

In order to evaluate the wear behaviour in gas operation, approx. 5,000 km were driven in pure gas operation and the valve wear was determined by changing the valve clearance.

In order to evaluate the reduction in wear caused by the additive system, 10,000 kilometres were driven with different settings. The wear was also recorded here via the change in valve clearance.

Up to test kilometre 12,000, approximately half the dosage of the manufacturer’s recommendation was used before the dosage was increased to the manufacturer’s specification after test kilometre 12,000.

Figure 3: Wear rate after dosage

At full dosing, no wear was detectable within the measurement accuracy.

Figure 4: Wear rate after dosing

Conclusion: Long-term verification after 105,000 km. This result clearly shows that the use of V-LUBE has significantly reduced wear. In unadditivated LPG operation, the vehicle would probably have failed at test kilometre 20,000 due to loss of compression.

As Figure 4 shows, there is no evidence of wear when dosing according to the manufacturer’s specifications, although the vehicle also shows wear in petrol operation. According to the vehicle manufacturer, the valve clearance should be checked every 60,000 kilometres.

It can therefore be stated that the correctly dosed valve protection extends the service life of the valves sufficiently so that they last the full life of the vehicle.

Study 4 Catalyser test

Study report on the scientific evaluation of catalytic converter ageing on a long-term test vehicle with the wear protection additive V-LUBE Valve Saver. Carried out at the Saarland University of Applied Sciences.

In Study 4, the effects of long-term use of V-LUBE Valve Saver on the catalytic converter were to be investigated. Recurring reports of catalytic converter damage when using valve protection additives prompted us to investigate the effects of V-LUBE Valve Saver after long-term use – with positive results.

Procedure: As part of the commissioned study, the Automotive Powertrain Institute of the Saarland University of Applied Sciences analysed a vehicle converted to LPG / liquefied petroleum gas. LPG generally causes higher loads on the charge exchange valves. The vehicle under investigation, a Toyota Corolla Verso 1.8 VVT-i (94 kW/129 hp), was operated in a long-term driving test with an additive to increase the stability of the valves (V-LUBE Valve Saver) using LPG as fuel, and a significant reduction in wear could be demonstrated at this point.

Now the functionality of the catalytic converter is to be tested in order to be able to assess the negative influences of the additive on its service life.

At the time of the test, the vehicle had reached a mileage of 148,000 km, of which 126,000 km had been run on LPG and the valve protection additive „V-LUBE Valve Saver“.

Conclusion: The measurement results of the catalytic converter test from the exhaust gas measurements prove that the long-distance use of the V-LUBE Valve Saver additive over 126,000 km did not have a negative effect on the function of the catalytic converter.

The determined conversion rates are positive and show that the catalytic converter of the test vehicle is still functional even after a long-term test.

No malfunction of the catalytic converter could be detected in this test. In view of the high mileage of the test vehicle in particular, no negative effects of the V-LUBE Valve Saver wear protection additive used on the exhaust gas aftertreatment system could be detected.