- Product description

- Spare parts

LPG filling hoses are used for refuelling refillable gas bottles, camper propane tanks, autogas tanks with 4-hole technology or LPG tanks. Due to their larger diameter, they offer a greater gas flow rate compared to conventional filling hoses made of copper or thermoplastic hose.

CAMPKO filling hoses are highly flexible and allow easy installation even in tight spaces.

Technical data

Length: 0.25 m - 3.00 m (special lengths are possible)

Outer diameter: 19 mm

Inner diameter: 12 mm

Thread: 3/4-16 UNF

Width across flats union nut:22 mm

Homologation: 67R-01 Class 1

Safety and warning information

User instructions for LPG high-pressure hoses for refuelling gas tanks and refillable gas bottles

1. introduction

Thank you for choosing our LPG high pressure hose. This product has been developed to transport LPG safely. Please read these instructions carefully before using the product and keep them for future reference.

2. safety instructions and warnings

General safety instructions

Safety hazard: LPG (liquefied petroleum gas) is highly explosive. Improper handling can lead to serious injury or damage to property.

Proper installation: This product may only be installed and serviced by trained specialists.

No self-conversion: Do not modify the hose or the connections without authorisation.

Dangers due to leaks

Before each use, check whether the hose or connections are damaged or leaking. If leaks are suspected, stop using the product immediately and have it checked by specialised personnel.

Warning: Leaking LPG can lead to the formation of an explosive gas mixture. Avoid naked flames and sparks.

Hazards due to bursting of the hose

Ensure that the permissible operating pressure is not exceeded. Do not use the hose if there are visible cracks, signs of abrasion or other damage.

Note: The hose is designed for a maximum operating pressure of 30 bar. The pressure range is labelled on the product.

Dangers due to improper use

Only operate the high-pressure hose within the specified temperature ranges (-30 °C to +70 °C). Do not expose the hose to aggressive chemicals or extreme heat.

Dangers due to incorrect storage

Store the hose in a dry, cool place, away from direct sunlight and chemicals. Do not use the hose if it is visibly damaged.

3. product overview

Material: Highly resistant, pressure-resistant rubber with textile inlay.

Maximum operating pressure: 30 bar

Temperature range: -30 °C to +70 °C

Length: Variable 0.25 - 4.00 m, depending on version

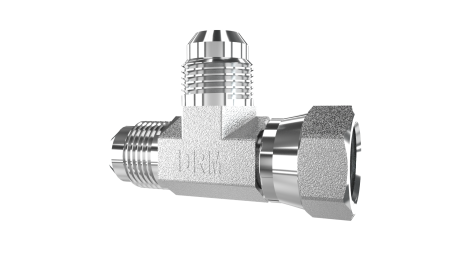

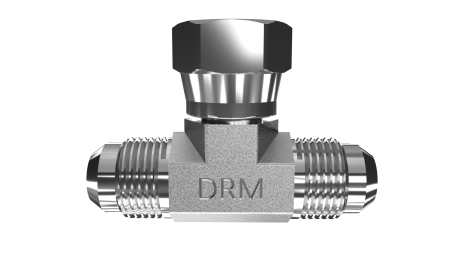

Connections: Special high-pressure connections according to ISO standards

Homologation: 67R-01 Class 1

4 Installation and operation

4.1 Installation

- Check the hose: Check the high-pressure hose and the connections for visible damage.

- Fit the connections: Connect the connections firmly to the LPG tank and the filling valve. Only use the appropriate connections.

- Leak test: Carry out a leak test by checking the connections with a gas leak detector. Note: Do not use naked flames to detect leaks!

4.2 Operation

During commissioning, monitor the connections for possible leaks during the entire refuelling process.

5 Maintenance and care

Regular inspection: Check the hose and connections regularly for visible damage and wear.

Cleaning: Use a soft cloth and mild detergent for cleaning. Do not use aggressive chemicals.

Replacement: Replace the hose if there is visible damage.

6. storage

Store the hose in a dry place away from direct sunlight. Ensure that the hose is not damaged by sharp objects.

7 Disposal

The product contains materials that should be sent for special recycling processes. Please dispose of the hose in accordance with local environmental regulations.

8 Warranty and liability

This product has been developed and tested in accordance with the requirements of the General Product Safety Regulation (GPSR). The warranty is void in the event of improper use, unauthorised modifications or improper installation. The manufacturer accepts no liability for damage caused by failure to observe these instructions.

Manufacturer contact information

Manufacturer Contact

HybridSupply GmbH

Roggenhorsterstr. 9b

23556 Lübeck

Germany

https:// hybrid.supply/contact